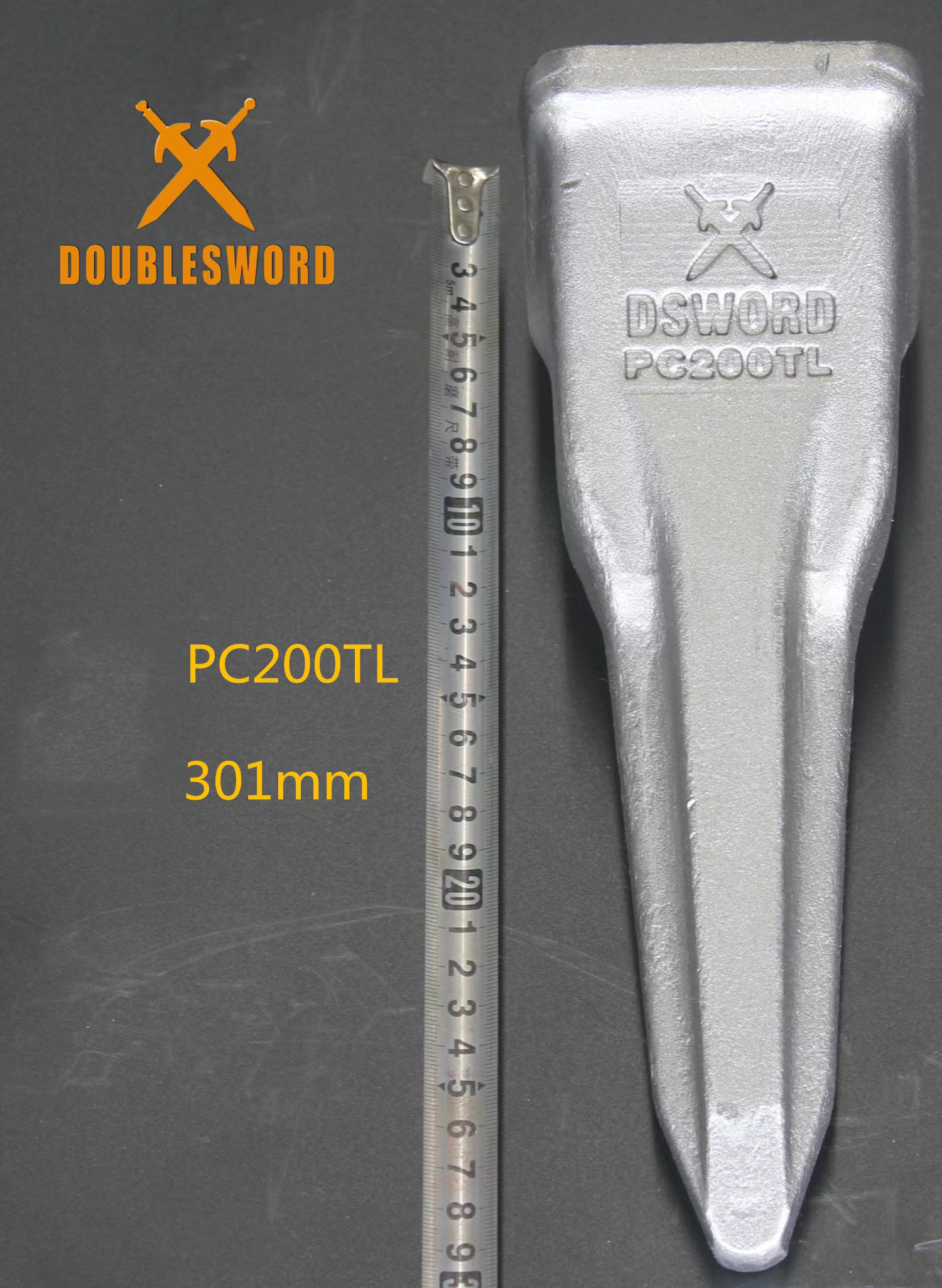

Ibhakethi izinyo lokubumba isixhobo sokwenza isixhoboIbhakethi Amazinyo ngexabiso levenkile

Ukubumba izinyo lebhakethi kunye nenkqubo yokuphosa:

Forging: Ikakhulu yenziwa yi-extrusion phantsi kobushushu obuphezulu.Iyakwazi ukucoca iinkozo kwiindawo, kunye ne-dense yangaphakathi kunye nokusebenza kakuhle.Ayisayi kubangela ukungcoliseka kwendalo.

Ukuphosa: Isinyithi esinyibilikisiweyo solwelo sigcwalisa umngundo wokupholisa.I-porosity kulula ukwenzeka phakathi kwendawo yokusebenza.Inkqubo yemveliso iya kubangela ungcoliseko olumandla lokusingqongileyo.

Amazinyo eebhakethi enziwayo asebenzisa oomatshini bokubumba ukwenza uxinzelelo kwizikhewu ezikhethekileyo zentsimbi, bazikhuphe kumaqondo obushushu aphezulu, bacokise imathiriyeli yekristale kwi-forgings, kwaye bayenze ibe yi-deformation yeplastiki ukuze bafumane iipropathi ezithile zoomatshini.Emva kokubumba, isinyithi sinokuphucula isakhiwo sayo, esinokuthi siqinisekise ukuba amazinyo ebhakethi yokubumba aneempawu ezintle zoomatshini, ukuxhathisa okungaphezulu, kunye nobomi obude benkonzo.Ukuphosa kukunyibilikisa isinyithi kwiqondo lokushisa eliphezulu, ukongeza izinto ezincedisayo, ukujova isikhunta, kwaye ufumane ukuphosa emva kokuqina.Ukugalela eziveliswe le nkqubo kulula ukuvelisa imingxunya yomoya kwaye benze imingxunya yesanti, kunye neempawu zayo mechanical, banxibe ukuxhathisa kunye nobomi benkonzo zingaphantsi kwezo forgings.Bucket Amazinyo wholesale ixabiso.

Amazinyo ee-emele ahlulwe ngokubanzi abe ngamazinyo okuphosa amabhakethi kunye namazinyo ee-emele enzelwa ngokweendlela zawo zokwenziwa.Ukusebenza kweendlela ezimbini zokuvelisa zahlukile.Ngokuqhelekileyo, amazinyo ebhakethi enziweyo ayakwazi ukunxiba, anzima, kwaye anobomi obude benkonzo, obuphindwe kabini kunamazinyo eebhakethi, kodwa ixabiso li-1.5 kuphela.Amazinyo ebhakethi yinxalenye ebalulekileyo ye-excavators kunye ne-forklifts.Kule mihla, amazinyo ebhakethi enziweyo asetyenziswa kakhulu.Amazinyo ebhakethi enziweyo akhutshelwa ngumxokozelo we-hydraulic wokubumba (i-hot forging hydraulic press, i-hot die forging oil press) ngokufa.

I-Bucket tooth forming press (i-excavator bucket tooth forging equipment) ithatha i-electro-hydraulic proportional control technology ukuze iqonde ulawulo lwedijithali loxinzelelo, isantya kunye ne-stroke, kwaye inokulawula ngokuchanekileyo ubungakanani bokubumba.Yamkela igxalaba elidityanisiweyo isakhiwo sesakhelo kunye nozinzo olufanelekileyo jikelele.Zonke iisilinda zeoyile ziyi-plunger cylinders, kwaye i-workbench ehambayo izinzile ekuguquleni, kunye nesixhobo se-buffer.Isixhobo sikwafaneleke ukubanda kunye nokutshisa isinyithi, kunye nenkqubo yokucinezela izinto zeplastiki.Iyakwazi ukugqiba ukubunjwa kwamahhala, ukufa kunye nezinye iinkqubo.

Amanyathelo enkqubo eshushu yokubumba amazinyo ebhakethi yokumba:

Inyathelo loku-1: Inkqubo yokuvala isebenzisa ukuchaneka kokuchaneka, kwaye ukunyamezela okungenanto kobude obungenanto yi-± 0.5mm.

Inyathelo lesi-2: Inkqubo yokufudumeza isebenzisa i-medium frequency induction heat kwi-1150 ℃ ukufudumeza indawo yokusebenza ngokukhawuleza kunye nokunciphisa ukubunjwa kwesikali se-oxide.

Inyathelo lesi-3: Kwinkqubo ecaphukisayo, susa ulusu lwe-oxide olujikeleze ukuphazamisa okungenanto, kwaye kwangaxeshanye susa ulusu oluphezulu kunye nolusezantsi lwe-oxide ngokuvuthuza komoya, ukuze kuphuculwe umgangatho wobume bezinto zokubumba kunye nobomi benkonzo yokufa. , kwaye uqinisekise ukuba umlinganiselo wobude obungenanto ukuya kububanzi bungaphantsi kwe-2.5 ngexesha lokuphazamiseka.

Inyathelo lesi-4: Kwinkqubo evaliweyo ye-extrusion ye-compound, i-die ephezulu ihamba kunye nebhloko yokutyibilika ye-emele izinyo lokubumba i-press (i-excavator ibhakethi yezinyo lokubumba izixhobo) ukucinezela indawo engenanto de yonke imingxuma izaliswe ngesinyithi.Izinyo lebhakethi elingenanto lenziwa yi-sliding compound extrusion ye-fapper die kwi-mold.Ibhloko etyibilikayo yoshicilelo ibuyisela, ikhupha iinxalenye ezenziweyo ze-extrusion, kwaye zonke iinkqubo ze-extrusion zigqityiwe.

Inkqubo ekhethekileyo yokubumba amazinyo eemele:

Intsimbi engqukuva ifudunyezwa kwiqondo lobushushu elifunekayo ukubunjwa emva kokugqunywa ngokobungakanani, ize ke ibekwe ngokuthe tye kwindawo engumngxunya yangaphambili ukuze ibunjwe ize ijike ibe ngama-90 ° ukubunjwa kwakhona.Umgodlo wangaphambili wokugoba usicaba unesiphelo esinye esingqindilili kunye nesiphelo esinye esibhityileyo.Isiphelo esicekethekileyo sendawo engenanto eyenziwe yabekwa ngokuthe nkqo ibekwe ezantsi kumngxuma wokugqibela.I-wedge punch iyahlukana kwaye ikhuphe into engenanto ezantsi.Emva kwamaxesha ama-4 ukuya kwe-5 yokubumba, isithuba esingenanto sibunjwa kwi-forging blank, emva koko, i-forging blank isenziwa ngoomatshini kwaye iphathwe ubushushu.Indawo engenanto icutshungulwa ibe yimilo ye wedge efana ne-emele izinyo imilo ngoku forging kwangaphambili.Emva koko, i-groove kwingcambu yamazinyo ebhakethi yenziwa ngokucanda kunye nokukhupha ingcambu ye-emele yezinyo nge-punch ye-wedge ngexesha lokugqibela.Isiphumo sokwenza silungile, ukudiliza kulula, kwaye ukusebenza kakuhle kuphezulu.Ngaphezu koko, ukusebenza koomatshini bezinyo lebhakethi kuphezulu kakhulu kuneemveliso ezicutshungulwa ngokuphosa.Ngokulungiswa komngxunya wangaphambili kunye nomgodi wokugqibela wokubumba, isibonelelo somatshini sincinci kwaye iindleko zokusetyenzwa ziphantsi, Ukusetyenziswa kwamandla aphantsi, akukho kungcoliseka kwendalo.

Ixesha lokuposa: Nov-28-2022